Special Metals is one of the UK’s leading metal fabrication companies.

Our fabrication services first started in 1969. But it was in 2004 that we established ourselves as a limited metal fabrication company – specialists in the supply and manufacture of metal products. We are masters of our craft. Collectively, we have over 120 years’ experience in the industry. And by calling upon that experience, we can fabricate the ideal metal parts for your requirements.

The perfect metal fabrication partner

Our approach – as a premier metal fabrication company – is to become an extension of your team. Your satisfaction as the client is paramount. And if you select us as your metal fabrication partner, we will treat your project as if it’s our own and deliver the highest quality results every time.

A comprehensive range of metals

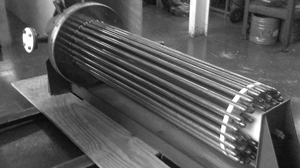

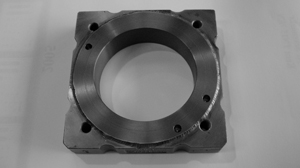

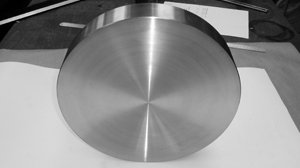

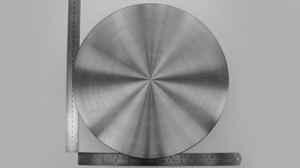

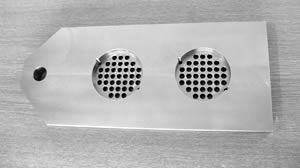

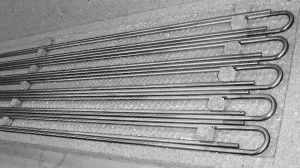

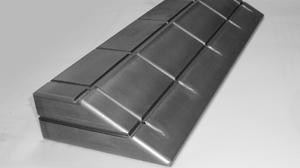

Refractory metals are our forte. We currently work with molybdenum, tantalum, tungsten, zirconium, niobium, titanium and pyrolytic graphite – and have a deep understanding of the properties and features of each. These metals can be supplied as standard metal parts (e.g. sheets, plates, rods etc.) or, by applying our expertise, they can be transformed into a metal fabrication of your choosing. But either way, we offer a fast and reliable turnaround on all orders.

Specialist fabrication techniques

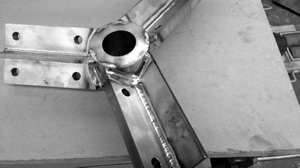

We’re not just metal suppliers. Over the years, our craftsmen have honed their skills on a variety of projects and are now incredibly talented metal fabricators. What’s more, our fabrication workshop is continuously updated with the latest equipment and state-of-the-art machinery. And as a result, we’re able to offer a diverse range of specialist metal fabrication techniques.

These include (but are not limited to):

- cutting

- casting

- drawing

- forging

- folding

- extrusion

- punching

- stamping

- assembling

- CNC machining

- welding

- aqua blasting

- bead blasting

No job is ever too big or too small. Whether you need a relatively simple metal part or one that is intricate and complex, we’re confident in our ability to make it a reality. We’re always ready to push the boundaries of metal fabrication and can advise on the best ways to optimise your design.

Contact our metal fabrication experts

To get started, simply contact our team and send your initial design ideas.

We have no minimum order levels and, having viewed your design, we can provide a free ‘no obligation’ quote for your project. Despite being an industry-leading metal fabrication company, our rates are extremely competitive. Customer satisfaction is at the heart of everything we do. And our goal is to create the highest quality parts, to your required deadline and for the best possible price.

More information on our services can be found in the ‘news’ section – including why, out of all the metal fabrication companies in the UK, we believe you should choose us. But if you have a question, or would like to discuss your latest project in detail, please feel free to give us a call on 01268 820409 or send an email to sales@special-metals.co.uk. We’re always happy to help.

FAQ's

Do I need a metal fabrication company?

For some projects, of course, a standard ‘off-the-shelf’ product will be the cheaper option and still do the job required. However, nine times out of ten, it’s worth spending that little bit extra and recruiting the help of a specialist metal fabrication company – such as Special Metals.

Detailed information on the benefits of our fabrication services can be found in our blog. But in a nutshell, it’s all about value. Working closely with you as the client, we will conduct thorough research and identify the most appropriate materials and methods to make your design a reality.

There’s no need to compromise or make the most of a component that isn’t quite right. You’re given much greater choice in terms of the refractory metals and specialist fabrication techniques available. And as all components are made in-house – 100% bespoke to order – you’re guaranteed to receive a high-quality metal part, that perfectly suits your requirements and will provide long-term value.

What type of project can you help with?

Absolutely any. It doesn’t matter how big or small the job, or how simple or complex the product. If you require a metal fabrication service, our team of experts are always ready to help.

We’ve collaborated with a diverse range of industries in the past, including the aerospace, automotive, pharmaceutical, military and construction industries, to name just a few. By applying our industry-leading skills, we have created high-quality metal parts for each and every one of our clients – and we could do the same for you. We’re always excited by the prospect of a new challenging project. So, why not send over a copy of your design ideas and get started?

How much do you charge for metal parts and fabrication services?

This depends on several factors, including whether you require a standard or bespoke metal part, the refractory metals used and the complexity and timescale of the fabrication project.

But rest assured, one of our main goals is to offer excellent value for money. We may be one of the best of metal fabrication companies in the UK, but our rates are competitive. We have no minimum order values and can provide a ‘no obligation’ quote for all jobs. To get a better idea of how much your metal fabrication project would cost, either call us on 01268 820409 or send an email to sales@specialmetals.co.uk.